Calf barns and shelters

Proper calf shelters (barns) that are correctly selected and managed have a significant impact on optimum calf growth and well-being in the first 24 months. Thanks to the use of the right products and good workmanship, calves can be fertilized earlier, growth increases, calf loss significantly decreases and milk production increases after the first two lactations. As a result, together with labor and time savings, more profitable operating environment and conditions occur. Calf shelters where we spend effort, time and money for the future and gain of our herds can cause losses.

Calf barns, calf fields and Calf hutches

Main causes of calf losses

- Prenatal applications

- Applications during the birth process

- Breeding system first 8 weeks (40 days)

- Shelter model

- Maintenance practices

For happy calves… It is to choose and use calf shelters and living space in accordance with the nature of the animal.

When choosing a Calf hutches

If the calf huts that are suitable for the shelter conditions are not selected, the huts you buy may harm you and the animal rather than benefit.

- According to the areas of use : For outdoor areas (UV protective) / For covered areas / For closed areas

- By cleaning system : Wheeled (mobile) / Raised sheds / Tilting / Liftable / Fixed

- According to calf age : 0-4 weeks / 0-6 weeks / 0-8 weeks

- By size : Small / Medium / Large

- By shelter shape : With Gate / Garden (fence) / Hybrid / Group

- According to its material: Fiber (Fiberglass and reinforced polyester) / Polyethylene / Galvanized / Aluminum / Plastic

Calf Hutches and use

Appropriate calf shelters (barns) are essential to ensure optimum conditions for rearing. Labor, prosperity and growth optimally contribute to calf rearing . Various models of calf sheds provide maximum efficiency with minimum work. In addition, services and accessories that make calf care easier are also important. For detail

Workmanship

Labor costs are becoming more important in terms of the operational management of today’s dairy farmers.

SUEVIA PE (polyethylene) material / calfotel® glass fiber reinforced polyester is made smooth and easy to clean material. Calf huts are very easy to remove and requires almost no effort to replace or clean their litter. His daily routine is more comfortable, fast, easy and therefore more efficient! Thanks to the wheels integrated into the plastic threshold, it is easy to transport for cleaning and to be carried to other places. A spout bucket and an information track record sheet can be attached to each corner of the fence, it can be quickly and efficiently renewed and easily identified. It is very easy to clean and renew grill mats and beds with a system with a smart lock and a hinged door that can be opened with one hand.

As a result; We focus on ergonomics, ease of use, accessibility, flexibility, mobility, hygiene and durability during the development and production of calf shelters and systems .

Comfort

Healthy young livestock is the basis for maintaining a balanced growth and a high-yielding dairy herd. In other words, for future gains. Medical care costs should be kept as low as possible and even avoided altogether. Fresh air, fresh water, high quality feed and hygienic environments are prerequisites for raising healthy calves. It makes the best contribution to healthy and fast growing cattle. It keeps the inside with dry and clean air while making the proper air circulation in the huts through the ventilation holes in the front of the roof.

Growth

Happy Calf Happy Farmer

Healthy calves grow fast and require little attention. The healthier a calf is, the better it develops during the first three months. Especially in the first three months, it can be easily seen that our systems are highly effective in terms of calf development. With open-top models where you can easily follow the calf huts, you always keep an eye on them, so you can intervene more quickly, which is a good reason to reduce your costs.

Our calf rearing systems facilitate the welfare and growth of calves while helping to reduce labor costs. Healthy calves mean less care and worry for the farmer. In other words: Happy calf, Happy Farmer!

Calf huts are made of durable, fiberglass reinforced polyester or polyethylene plastic and have the following advantages: Strong and robust structure with a long service life, sheltered from heat, cold and air flow, the huts create the most suitable microclimate for calves. The interior of the shelter has a smooth surface that prevents bacterial growth, making it easy to clean. The kennels are easy to transport, making it easy to clean.

HEAT in the Calf Shed

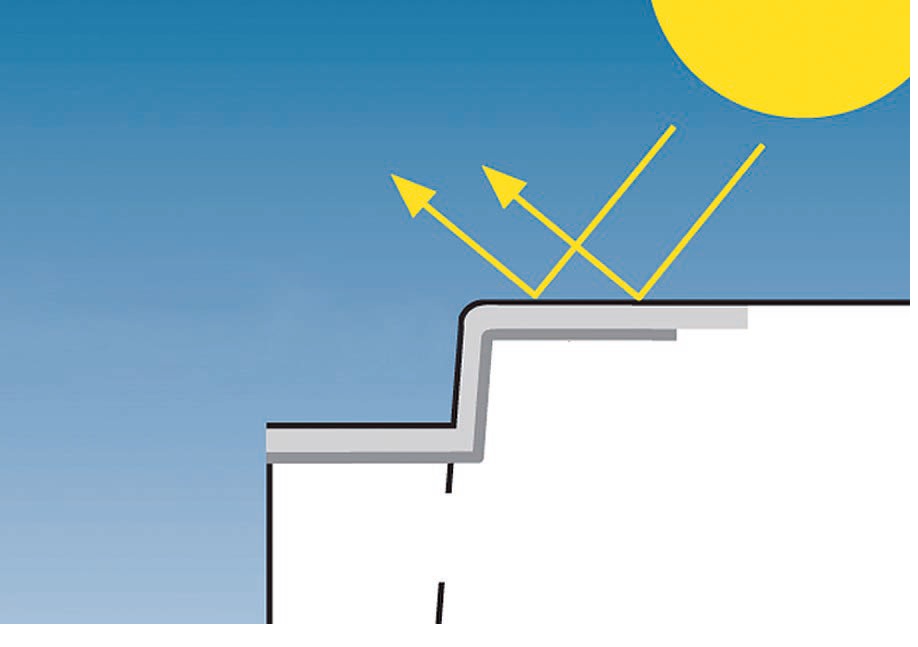

Thanks to the combination of heat reflective (white) color, correct (glass fiber reinforced polyester) material and a heat resistant inner layer, CalfOTel® keeps the inside temperature of calf huts much lower than other materials such as PE (polyethylene). Calves feel more relaxed and less stressed while promoting growth and reducing their susceptibility to disease. What’s more, the bacteria inside the calf shelter grow less at lower temperatures.

Solar radiation temperature inside calf hut

The transparency and UV permeability of CalfOTel® calf huts are visually lower than other barn sheds. The calf inside is not disturbed as it prevents heat and sun rays. Low temperature also facilitates the farmer’s work.

The material we use has a UV protective layer to ensure that our calf sheds stay at a suitable temperature. Also, the material is bright white. As a result, the light transmittance of CalfOTel® calf sheds is much lower than that of other brands.

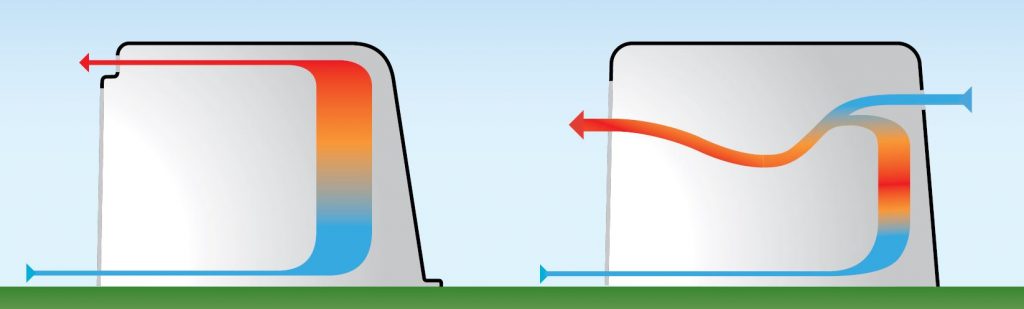

Draft is a disaster

Draft-free weather conditions are a very important factor in the well-being of calves. It is vital to evacuate carbon dioxide and gaseous ammonia from the calf shed and to ensure that the air is constantly replenished with fresh oxygen, but drafts should be avoided. Calves can be in contact with other diseases due to cold and drafts. CalfOTel® calf sheds only have openings on one side, ie fresh and clean air is supplied from the front while contaminated air is expelled. This prevents unnecessary air vortex in the calf shed by creating a smooth, continuous air flow.

Similar kennels often have rear vents, causing cold air to mix with warm air.

Draft occurs as a result of a phenomenon where hot air cools and then collapses

In other brand kennels, the airflow is at head height and more uncomfortable for calves. The bright white material we use has a UV protective layer to keep the calf huts at a suitable temperature. As a result, the light transmittance of CalfOTel® calf shelters is much lower than other brands. The transparency and UV permeability of calf huts are visually lower than other barn sheds. It does not disturb the calf inside as it prevents heat and sun rays. Low temperature makes it easier for the farmer to work.

Climate in calf barns

Calf barns or rooms can be ventilated naturally or mechanically. Natural ventilation combined with a positive pressure ventilation tube (PPVT) system provides the best of both in calf barns.

There are four primary goals for ventilating calf barns or rooms:

- Remove moisture in cold weather,

- Remove heat in hot weather,

- Provide fresh air uniformly, and

- Provide fresh air without causing drafts.

Calves from birth to weaning require 17 m3/h (10 cfm) of fresh air per calf in the winter to remove the moisture. They produce and 170 m3/h (100 cfm) of fresh air per calf in the summer to remove heat. However, the actual air exchange required is usually greater than the minimum ventilation requirements. In winter calves need four room air changes per hour, and in summer 40 or more air changes per hour. The challenge with calves is to provide the small amount of winter ventilation needed evenly, and without drafts. A draft in this case is defined as air moving at speeds greater than 0.3 m/s (60 feet per minute).

Calf cages and usage

Don’t let calf deaths be your nightmare! Calves should be protected carefully between 0-8 weeks. The ground of their shelters should be kept dry, clean, soft, protected from the wind, away from human and animal contact and effects.

For economical and most sanitary solutions, it is recommended to use raised huts, raised calf cages or calf fields with raised floors .

Raised calf cages:

Thanks to the bottom floor of grid wire or sheet material raised at least 15 cm from the ground with the feet, any urine and discharge from the calf flows directly down and the floor on which the animal lies remains dry.

- Thanks to the bottom floor of grid wire or sheet material raised at least 15 cm from the ground with the feet, any urine and discharge from the calf flows directly down and the floor on which the animal lies remains dry.

- By mounting a special CaBoMat KRAIBURG rubber mattress on this hard ground, the required softness for the animal is provided on this non-slippery ground.

- The sides of the cage are placed between the animals with plastic or PVC or other materials when necessary, and the calves are isolated from contact with other animals.

- During daily cleaning, feces and other currents that go under the grill floor without interfering with the animal are cleaned by hand scraper and / or other methods.

- After the animals are taken from the cage at the end of 6-8 weeks, the cage and its bottom are washed with pressurized water, detergent and disinfectant and prepared for the new calf.

Calf field with raised floor

The calf field (barns) has a canal on the lower floor and there are calf areas (fields) with grill floors working with a scraper in this channel.

A special LOSPA KRAIBURG rubber mattress is mounted on this ground made of wire or sheet metal, providing the necessary softness for the animal on this non-slippery ground.

- These floors are made with plastic MIK or Cemented Metal grid or Grid Concrete . In this way, all kinds of feces formed in the field and all kinds of urine and discharge from the calf flow directly downwards and the ground where the animal lies remains dry.

The channel at the bottom is based on the project status:

- with automatic scraper

- By flushing with the flushing method.

- With the help of a tractor, contact with animals is not provided during daily cleaning.